How to Choose the Perfect Gaming PC Rental for Your Needs

July 24, 2024

Liquid Cooling vs Air Cooling: Which cooling system is best for gaming computers in 2024?

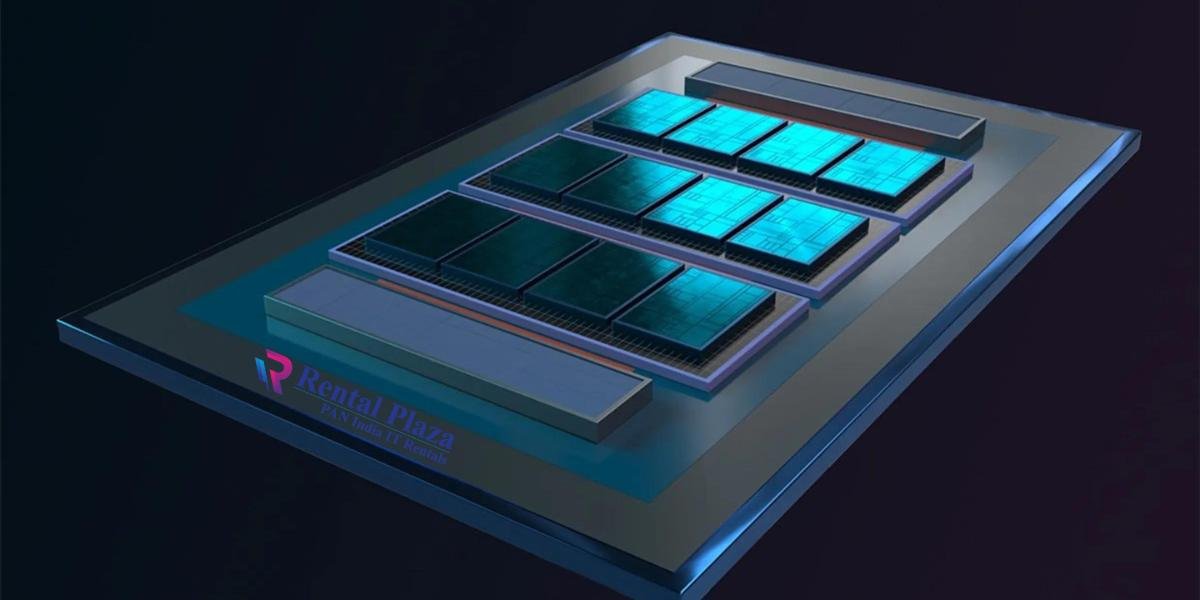

October 1, 2024The semiconductor industry is constantly evolving, with each new process node pushing the boundaries of what is possible in terms of performance, power efficiency, and scalability. Intel’s 18A process technology is one of the most significant advancements in recent years, representing a major leap forward in chip design. This cutting-edge process introduces two key innovations: nanosheet transistors, known as RibbonFET, and backside power delivery. These technologies are set to redefine the landscape of semiconductor manufacturing and enable the next generation of high-performance computing devices. In this blog, we will delve into the details of Intel’s 18A process, exploring how nanosheet transistors and backside power delivery work, and the profound impact they are expected to have on the industry.

The 18A Process: A New Era in Semiconductor Manufacturing

Intel’s 18A process is part of the company’s IDM 2.0 strategy, which aims to reclaim leadership in semiconductor manufacturing by developing and deploying the most advanced process technologies. The “18A” designation refers to the process node’s feature size, which is 18 angstroms, or 1.8 nanometers. This is an extraordinarily small scale, pushing the limits of Moore’s Law and enabling a dramatic increase in transistor density.

The transition to the 18A process is not just about shrinking feature sizes; it also involves a fundamental shift in transistor architecture and power delivery mechanisms. These innovations are crucial for meeting the ever-growing demands of modern computing, where performance, efficiency, and scalability are paramount.

Nanosheet Transistors (RibbonFET): The Next-Generation Transistor Architecture

At the heart of Intel’s 18A process are nanosheet transistors, also known as RibbonFET. This new type of transistor architecture is a significant departure from the FinFET (Fin Field-Effect Transistor) design that has dominated semiconductor manufacturing for the past decade.

From FinFET to RibbonFET: What’s the Difference?

FinFET transistors are designed with a fin-like structure that rises above the silicon substrate, providing more surface area for current to flow and improving control over the transistor’s on/off state. While FinFETs have been incredibly successful, they face challenges as feature sizes continue to shrink. The fins become narrower and taller, leading to increased variability and difficulty in manufacturing.

RibbonFET, or nanosheet transistors, address these challenges by replacing the fin structure with stacked horizontal nanosheets. These nanosheets are thin, ribbon-like channels through which current flows, and they are surrounded by the gate on all sides. This gate-all-around (GAA) architecture provides even greater control over the transistor’s switching behavior, reducing leakage current and allowing for more aggressive scaling of transistor dimensions.

Advantages of RibbonFET

The RibbonFET architecture offers several key advantages over FinFET:

- Better Electrostatic Control: The gate-all-around design improves control over the channel, reducing leakage and enabling more precise switching. This is particularly important as transistors become smaller and more densely packed.

- Scalability: RibbonFET transistors can be scaled to even smaller dimensions than FinFETs, allowing for continued advancements in transistor density and performance.

- Customization: The width of the nanosheets in a RibbonFET can be adjusted, enabling designers to fine-tune the balance between performance and power efficiency for different applications. This flexibility is crucial for optimizing chips for specific use cases, whether they require maximum performance or minimal power consumption.

- Improved Performance and Efficiency: The enhanced control and scalability of RibbonFETs result in higher performance per watt, making them ideal for both high-performance computing and energy-efficient mobile devices.

Backside Power Delivery: A Revolutionary Approach to Power Management

In addition to RibbonFET transistors, Intel’s 18A process introduces another groundbreaking innovation: backside power delivery. This technology represents a fundamental change in how power is distributed within a chip, with far-reaching implications for performance, efficiency, and design flexibility.

Traditional Power Delivery vs. Backside Power Delivery

In traditional semiconductor designs, power and data interconnects share the same layers on the front side of the silicon wafer. This approach has served the industry well for many years, but it also has limitations. As transistors become smaller and more densely packed, the congestion of interconnects on the front side can lead to increased resistance, voltage drops, and signal interference. These issues can negatively impact performance and power efficiency.

Backside power delivery addresses these challenges by relocating the power interconnects to the backside of the silicon wafer, completely separating them from the data interconnects. This separation provides several key benefits:

- Reduced Resistance and Voltage Drop: By placing power interconnects closer to the transistors and away from data interconnects, backside power delivery reduces the resistance and voltage drop associated with power distribution. This leads to more stable and efficient power delivery, which is especially important for high-performance computing applications.

- Increased Signal Integrity: With power and data interconnects on separate layers, there is less chance of interference between them. This improves signal integrity, allowing for faster and more reliable data transmission.

- More Space for Data Interconnects: By moving power interconnects to the backside, more space is freed up on the front side for data interconnects. This allows for higher interconnect density, which can improve the overall performance of the chip.

- Enhanced Thermal Management: Backside power delivery can also help with thermal management, as it allows for more efficient heat dissipation. This is crucial for maintaining performance and reliability in high-power chips.

The Impact of Intel’s 18A Process on the Semiconductor Industry

The introduction of nanosheet transistors and backside power delivery in Intel’s 18A process is poised to have a profound impact on the semiconductor industry. These innovations address some of the most pressing challenges facing chip designers today, including scaling, power efficiency, and performance.

Enabling the Next Generation of High-Performance Computing

The 18A process is expected to power the next generation of high-performance computing devices, from data center processors to AI accelerators and consumer PCs. The combination of RibbonFET and backside power delivery enables these devices to achieve higher performance per watt, which is critical for meeting the growing demands of modern workloads.

Reinforcing Intel’s Leadership in Semiconductor Manufacturing

Intel’s 18A process is also a key component of the company’s IDM 2.0 strategy, which aims to reestablish Intel as a leader in semiconductor manufacturing. By offering these advanced technologies to both its own product teams and external foundry customers, Intel is positioning itself as a key player in the global semiconductor ecosystem.

Driving Innovation Across the Industry

The innovations introduced in the 18A process are likely to inspire similar advancements across the semiconductor industry. As other companies develop their own nanosheet transistors and explore backside power delivery, we can expect to see a wave of new technologies that push the boundaries of what is possible in chip design.

Conclusion: A Game-Changer for the Future of Chip Design

Intel’s 18A process technology represents a game-changing advancement in the semiconductor industry. By introducing nanosheet transistors and backside power delivery, Intel has addressed some of the most significant challenges facing chip designers today. These innovations not only enable higher performance and efficiency but also pave the way for continued scaling and innovation in the years to come.

As Intel continues to develop and deploy its 18A process, the impact on the semiconductor industry will be profound. From high-performance computing to energy-efficient mobile devices, the 18A process is set to power the next generation of technology, driving the industry forward and enabling new possibilities for the future of computing.